This website uses cookies so that we can provide you with the best possible user experience. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helps our team understand which sections of the website are most interesting and useful to you.

Devices

Scan Analyzer 3D

Scan Analyzer 3D scans the environment, e.g. a storage area, in three dimensions and identifies objects and free spaces, such as coils, storage locations, loading areas of trucks or wagons, for example, and is able to detect any obstacles. The data is transmitted in real time to the higher-level system for further processing.

- Scan Analyzer 3D Basis describes the basic system structure

- Scan Analyzer 3D Details describes the extensive functionality of the system.

Crane Pilot

Crane Pilot enables fully automatic operation of a bridge or gantry crane. It takes over the complete control of the crane and the manipulation of the goods, such as coils, and the processing of all transport orders to be carried out.

- Crane Pilot Overview describes how the system works.

Pendulum Damping

Our pendulum damping system (PendDamp) actively reduces pendulum movements in overhead cranes by directly controlling the crane and trolley drives. It can be used independently or with our CranePilot.

- Direct control interventions: Reduces oscillating movements by adjusting the drives.

- Flexibility: Works independently or with the CranePilot.

- Real-time data processing: Uses sensor data for real-time damping; calculates and implements adjustments immediately.

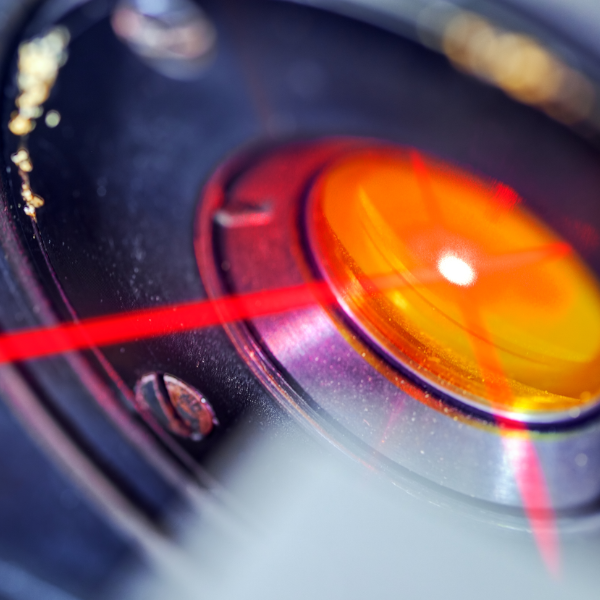

- Sensor integration: Uses Scan Analyzer or 3-axis vibration sensor.

- Comprehensive data acquisition: Processes speeds, positions, acceleration and lift height.

Vibration Monitor

Our Vibration Monitor prevents surface defects such as chatter marks by recording and analyzing vibrations during grinding. The system uses a vibration sensor and an evaluation device to detect critical conditions.

- Permanent monitoring: Detects and reports critical vibrations in real time.

- Data archiving: Saves vibration signals for later analysis and quality assurance.

- Online visualization: Displays real-time data on the machine and in the Roll Works Explorer.