This website uses cookies so that we can provide you with the best possible user experience. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helps our team understand which sections of the website are most interesting and useful to you.

Scan Analyzer 3D

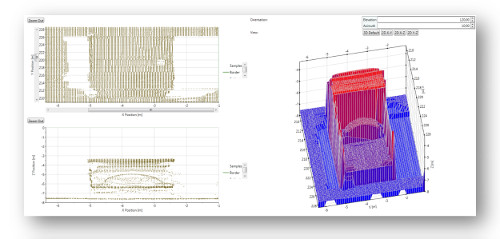

Our Scan Analyzer 3D scans the environment, e.g. a storage area, in three dimensions and identifies objects and free spaces, such as coils, storage locations, loading areas of trucks or wagons, for example, and is able to detect any obstacles. The data is transmitted in real time to the higher-level system for further processing.

Scan Analyzer 3D was developed as a system component for our own system solutions and is used for object detection, making it an ideal component of fully automated systems, such as automatic bridge and gantry cranes, among others. Thus, Scan Analyzer 3D also represents a standard component of our CranePilot.

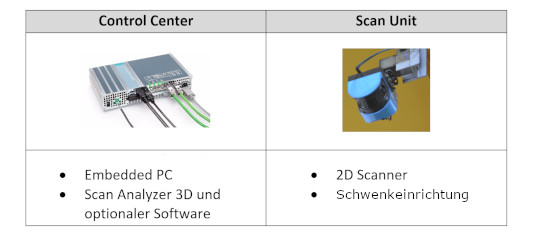

The system setup

Scan Analyzer 3D consists of several components. Up to eight combinations of one 2D laser scanner each in combination with a swiveling device (each combination of laser scanner and swiveling device can be moved in all three spatial directions!) scan the room 3D. The central software package running on an embedded PC calculates the edge contours of the surrounding objects from the acquired signals and is also able to detect objects of interest (e.g. coils).

Leverage the strengths of Scan Analyzer 3D

- Object detection, e.g. of coils

- Use in harsh industrial environment

- Minimum object distance of 10cm

- Possibility to connect up to eight sensor units consisting of 2D laser scanner and swiveling device

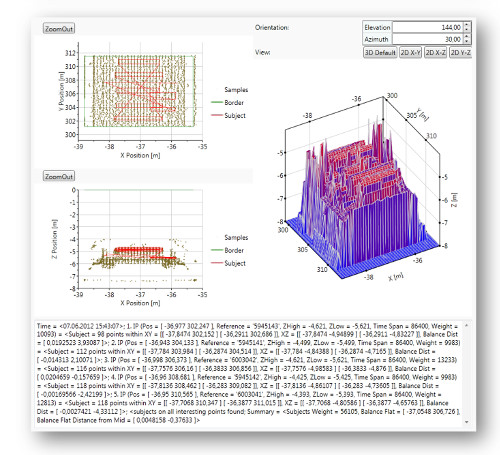

- The spatial coordinates are calculated, evaluated and transmitted to the higher-level system in real time

- Many years of experience in use

- Easy integration into customer systems

- Technical support

Examples for the use of Scan Analyzer 3D

- Stock level control by comparing the stock positions (free or occupied) with the data in the database.

- Loading control by scanning the loading areas of e.g. trucks or wagons

- Detection of geometric deviations of objects

- Collision warning

Why Scan Analyzer 3D is the right solution for your project

You are looking for a solution that detects and analyzes objects in real time based on their contours, and you want an innovative partner who already has many years of experience with object detection in industrial environments.

We would be pleased if we have aroused your interest in our Scan Analyzer 3D or other products and solutions from our company.

Details

The hardware of the Scan Analyzer 3D comprises an embedded PC (Control Center) and one or more 2D scanners, each with a swivel device (scan units). The number of 2D scanners in combination with a swivel unit depends on the requirements, such as measurement accuracy, measurement performance or the number of areas to be monitored (up to eight are possible).

With the 2D scanner in combination with the swivel device, the spatial coordinates are scanned in three dimensions. It is important to note that each of these combinations can optionally be moved in all three spatial directions! The signals acquired in this way are passed on to the software of the Scan Analyzer 3D.

The interface from the Scan Analyzer 3D to a higher-level system (customer system) is implemented by default by integrating a Windows DLL provided by us, or by using a proprietary TCP/IP-based interface. Alternative interfaces are possible in coordination with the technical conditions.

Below are some examples of how the data is calculated and evaluated in the system:

We would be pleased if we have aroused your interest in our Scan Analyzer 3D or other products and solutions from our company.