This website uses cookies so that we can provide you with the best possible user experience. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helps our team understand which sections of the website are most interesting and useful to you.

Roll Works

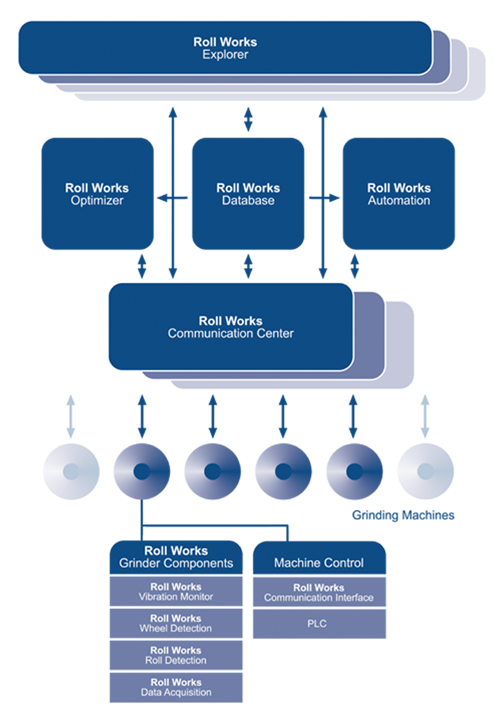

Roll Works is the system supporting everything essential around handling and grinding of rolls. It provides roll and wheel base data management as well as the possibility to enforce grinding requirements through the online connection interface to the grinding machines.

The most remarkable innovation is the Roll Works Optimizer – this system changes the way of grinding completely.

Reduction of costs through Roll Works is substantial (please see – without consideration of Roll Works Optimizer – Confirmation of voestalpine Stahl Linz).

Our solution for AI-driven optimization and extensive automation of all roll processing tasks, enabled through inline interfaces with grinding machine controls, innovative measurement technology, and centralized task management via our Task Manager, seamlessly integrated with our Roll Shop Management System (RSMS).

- Roll Works Explorer

This is the front end application of the Roll Works System. It allows investigations on historical data (statistical reports up to detailed measurement and grinding parameter values), online views of machine states and manual inputs of base data and settings for grinding. For additional information and screenshots please see here. - Roll Works Optimizer

The Grinding Optimizer is a Learning Machine which automatically calculates and transfers to the grinding machine parameter sets to optimize grinding in the context of stock removal performance, roll surface quality, wheel wear, etc. For additional information please see here. - Roll Works Automation

This system ensures all the rules for roll handling defined by the roll shop people to be used during grinding transfers concerning commands to Communication Center. For additional information please see here. - Roll Works Database

Database system where all the data (from grinding machine, plants, manual inputs, etc.) are stored. Oracle and Microsoft SQL Server are supported. - Roll Works Communication Center

The Communication Center is the central unit to communicate with external and Roll Works internal components. For additional information please see here. - Roll Works Management

The Roll Shop Management System enables a holistic solution for efficient data management of roll inventory, maintenance and grinding processes, component management, optimizes resource allocation and promotes data-based decisions to improve roll shop operations. More information is available here. - Roll Works Grinder Components

Modules of the Roll Works System supplied by btec which require additional hardware components, e.g. Embedded PCs, antennas, sensors, etc., to be installed per grinding machine.- Roll Works Vibration Monitor

System for detecting and alerting on vibration occurrences which are dangerous to affect roll surface quality badly. For additional information please see here. - Roll Works Wheel Detection

System to identify wheels and so be able to capture wheel installation periods correctly and calculate report on them with a very high data base quality. Barcode technology can be used as well as RFID depending on the type of used wheels. - Roll Works Roll Detection

This RFID based system detects rolls automatically and can be used to automate nearly every roll handling procedure. It also ensures that report calculations are based on valid data. - Roll Works Data Acquisition

In many cases it’s not only interesting which values are entered by the operator (the collection of this is of course part of Roll Works) but also real physical values appeared on the machine. This system acquires values like wheel pressure, wheel speed, wheel infeed, roll speed, etc. and allows detailed investigations of machine behavior.

- Roll Works Vibration Monitor

- Machine Control

The intrinsic control of the grinding machine supplied by the manufacturer.- Roll Works Comm Interface

Integration of the Roll Works Communication Interface in the machine control. - PLC

Here the software for all movements of the machine axis is implemented.

- Roll Works Comm Interface